In this year so peculiar due to the difficulties

related to the covid-19 pandemic, we at Algamoil have continued our research activities in the microalgae sector, activating new collaborations with Italian and foreign

universities.

With this in mind, we are particularly proud to announce the forthcoming publication in the prestigious international journal Journal of Environmental Chemical Engineering of a work entitled "Latest developments in wastewater treatment and biopolymer production by microalgae", relating to the latest discoveries in the applications of algae for the wastewater treatment and the production of bioplastics.

The research was led by Dr. Giovanni Antonio Lutzu, our lab manager (pictured), who

made use of the valuable contribution of colleagues and researchers from Italian and US universities. Specifically, the co-authors of the publication were: Prof. Nurhan Turgut Dunford of the

Department of Biosystems and Agricultural Engineering of Oklahoma State University, Dr. Alessandro Concas of the Center for Research, Development and Higher Studies of Sardinia, Prof.ssa Adriana

Ciurli of the Faculty of Agriculture of the University of Pisa, Dr. Carolina Chiellini of the Institute of Biological Agriculture and Biotechnology of the CNR of Pisa, and Dr. Fabrizio Di Caprio of

the Chemistry Department of the La Sapienza University of Rome.

The work offers a comprehensive overview of the use of microalgae as an efficient ecological strategy for the removal of contaminants from wastewater. Thanks to their

versatility, these photosynthetic organisms can grow in a wide spectrum of wastewater, including those from agricultural, animal, municipal and industrial sources, while converting nutrients such as

nitrogen and phosphorus into useful products. Currently, microalgae are starting to be exploited on a large scale for agricultural and urban wastewater treatment. However, new applications for

specific types of wastewater, such as from petrochemical sources, while producing promising results, are still in their early stages. Therefore, further work should be carried out to optimize

microalgae technology in light of its application to industrial settings.

Furthermore, there is also a growing interest in

making these technologies even more sustainable from an economic and environmental point of view by using microalgae biomass, obtained during the wastewater remediation

processes, to produce new bioplastic materials, capable of potentially replacing the counterparts based on oil and reducing the negative impact of human

activities.

We proudly announce that we have been selected among the "1000 solutions that can protect the environment in a profitable way" by the Solar Impulse Foundation, a society based in Switzerland born from the visionary project of the aviator Bertrand Piccard, consisting of

a solar-powered aircraft capable of take a complete tour of the planet.

Our business proposal was reviewed by an independent team of experts, who assessed it for feasibility, environmental benefits and profitability and judged it worthy of appearing in the foundation's 1000Solutions portfolio.

This concretely means that we are now part of an international network of innovators and investors, the

"World Alliance for Efficient Solutions", which offer services and technologies with the aim of achieving a sustainable economy and helping institutions to develop more ambitious energy

policies.

You can visit our dedicated page on https://solarimpulse.com/efficient-solutions/tere-group-srl

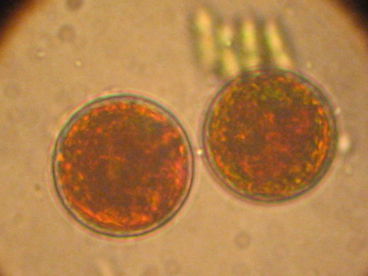

ASTAXANTHIN,

CULTIVATION FOR THE FOOD AND PHARMACEUTICAL SECTORS

Astaxanthin is a carotenoid with powerful antioxidant properties and multiple uses: it is a resource for the food, pharmaceutical,

aquaculture (fish and crustaceans) and poultry industries.

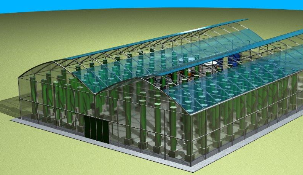

For the construction of our plants for growing algae, we have developed a new industrial concept, following our scientific research on the economic performance and profitability of the microalgae

production process on a commercial scale.

Our approach allows to obtain great economic benefits against considerably reduced production costs.

For details on the plants, call or write to info@teregroup.net.

(Photo: Wikipedia)

SPIRULINA START UP CULTIVATION SYSTEM

Displayed to a group of professional operators the new Start Up Kit produced by Algamoil for the cultivation, extraction and drying of Spirulina.

During the demonstration it was possible to separate Spirulina from water and operators could taste it fresh before and after drying. The same procedure was also possible with Chlorella.

It is now possible to purchase the Kit in our store where the manual or semi-automatic version is available.

The kit can also be hired up to 60 months.

PRE-AUTHORIZED AND AUTHORIZED AREAS FOR CONSTRUCTION SITES

New pre-authorized or authorized areas are available throughout the Italian territory and on part of the European one for the immediate construction of the plants. The

authorized areas have a building permit, so they can already be built, to immediately take advantage of the GSE incentives, while

the pre-authorized areas can be authorized according to the local urban planning regulation.

LABORATORIES IN MODENA

The laboratories will soon be moved to the new premises where all the activities, studies and research will be concentrated. The research will continue in cooperation with the University of Modena and american supervisors.

3D PRINTING WITH BIODEGRADABLE FILAMENTS MADE WITH MICROALGAE

The 3D printer filaments made with microalgae were developed at Teregroup, in cooperation with international partners. These filaments are perfectly compatible with every printer on the market.

Thanks to our technical office, Teregroup is able to make, with our 3D printer, items designed with CAD and challenging non-biodegradable items.

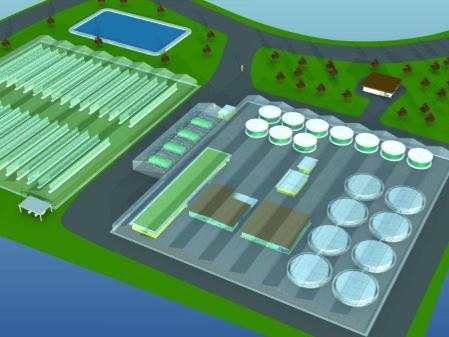

The figure above shows the 800-liter TG photobioreactor in Modena that reached its maximum productivity. After the test, this photobioreactor, along with about 100 others, will be placed in a 1000 square meters greenhouse (next picture) for the production of Microalgae like Spirulina. These Microalgae will be used to produce Biofuels, Bioplastics or Nutraceuticals.The figure above shows the 800-liter TG photobioreactor in Modena that reached its maximum productivity. After the test, this photobioreactor, along with about 100 others, will be placed in a 1000 square meters greenhouse (next picture) for the production of Microalgae like Spirulina. These Microalgae will be used to produce Biofuels, Bioplastics or Nutraceuticals.

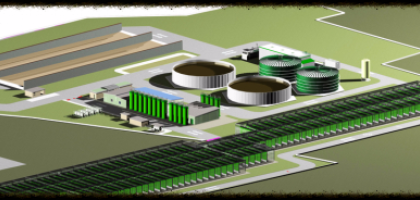

The 36000 square meters greenhouse has now been completed. This greenhouse will be part of the first French algal-biofuel production plant.

The new refinery specialized in green chemistry was presented in front of many reporters. The refinery will convert Teregroup algal oil into biodiesel. Among the speakers, Senator Saverio D’Amelio, Alderman to Agricultural and Forestry Policy Luca Braia, Alderman to Development Policy Raffaele Liberali and many others.

PARIS CLIMATE CHANGE CONFERENCE: IT’S A TURNING POINT FOR BIOFUELS PRODUCERS, TOO.

The draft agreement presented by the French Minister for Foreign Affairs states that: “We have to prevent global warming above 2 ºC by 2020.” The $100 billion deal for developing countries has been confirmed. Hollande: «This is a chance to change the course of history”; it is also as a result of the support of Teregroup and Algamoil consultants.

“This is an ambitious and balanced draft agreement, legally binding, and an historic turning point”. The French Minister for Foreign Affairs Laurent Fabius presented the draft agreement reached at the end of the climate summit in Paris, a draft agreement that will be then carefully examined by the plenary assembly. A deal that includes a five-year plan for each country to limit global warming. The agreement stipulates that “global warming must be kept well below the 2 ºC limit by 2020, even 1.5°”. The national plans for the reduction of greenhouse gases will be audited every five years. The $100 billion fund for developing countries has been confirmed, but nevertheless Fabius explains that «between now and the year 2020 it only represents a starting point; a new target should be set by 2025». Fabius concluded his speech recalling the words by Nelson Mandela: «None of use acting alone can achieve success, we must therefore act together as a united people».

«This agreement – as the French Minister for Foreign Affairs has pointed out – it’s necessary for the whole world and for each of our countries. It will help island states to safeguard against the advance of the sea prowling their shores; it will give financial means to Africa, will support Latin America in protecting its forests and will support oil producers in diversifying energy production even with the production of algal biofuels.»

Algamoil technology to cut emissions in power plants (especially in coal plants) was presented at COP21 Paris Climate Conference. The fumes are captured by a special hood and channelled through a series of vertical cylinders containing a certain alga able to convert emissions in oxygen. This is a great opportunity for our planet, a low-cost natural solution: a standard-sized plant is able to convert emissions in oxygen in the same way as a 400 hectares wood.

OUR POLLUTION-CONTROL PROPOSAL BASED ON THE USE OF OUR VEGETABLE FUEL AS ADDITIVE TO MINERAL FUELS WAS PRESENTED AT COP21 PARIS CLIMATE CONFERENCE (the video below shows the advantages)

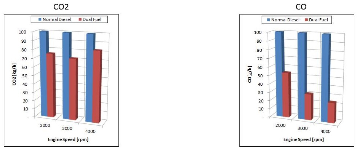

Test performed on Friday 27 November 2015 by University of Modena, Department Enzo Ferrari, on a VM 180-horsepower turbo engine normally mounted on Jeep Cherokee.

Mineral gasoil, added with 10% of algal biodiesel in accordance with European legislation that will enter into force on 2018, was used as fuel.

The result was a massive reduction in gas emissions, especially over 2000 engine revs.

TEREGROUP ANNOUNCES A NEW TECHNOLOGY TO BIOFILTER CARBON DIOXIDE AND DIGESTATE PRODUCED BY BIOGAS PLANTS

The Clean Power plan reports “State plans may allow the use of CCU (Carbon capture storage and utilization) technologies to reduce CO2 emissions affecting the atmosphere”.

It’s a great victory for algal industry, we have been working on this for more than one year. This law gives a new opportunity to companies which commercialize algal technologies and convert carbon dioxide produced by power plants in vegetable oil, feedingstuffs, fertilizers and other value products.

Our message is that carbon dioxide utilization is a common sense oriented approach, with the support of the whole US Congress. The growing importance of CO2 utilization will be reflected in an increase in state funding.

This new law will be taken as reference even in Europe…

FINALLY, A LAW ON BIOFUELS: COMPULSORY QUOTAS HAVE BEEN DETERMINED UNTIL 2022

Ordinance No. 10 ottobre 2014 of the Minister of Economy subject was published on the October 27 Gazzetta Ufficiale n. 250: “Updating of conditions, criteria and detailed rules for the implementation of the use of biofuels, including the most advanced”.

The Ordinance established that biofuels mandatory rates will be up to 5% of the release for consumption of gas and diesel in 2015, up to 5,5% in 2016, up to 6,5% in 2017, up to 7,5% in 2018, up to 9% in 2019, up to 10% between 2020 and 2022. Among the mentioned biofuels there are also biomethane and biopropane.

2018 innovation is that a part of the mandatory rate will be covered with “advanced biofuels”, obtained from wastes as raw materials and from non-food raw materials, listed in Annex 3 to the Ordinance: the rate will account for 1,2% in 2018 and 2019, for 1,6% in 2020 and 2021 and for 2% in 2022.

TEREGROUP AND ALGAMOIL AT ECOMONDO KEY ENERGY IN RIMINI (ITALY)

Teregroup in cooperation with Algamoil partecipated to Ecomondo Key Energy attracting considerable visitors interest. In particular we thank all our clients that visited us and all our collaborators that stayed available for 4 days to the persons requiring technical and commercial informations.

We also thank the host for the great work he did.

We’ll see you next year.

TEREGROUP IN COOPERATION WITH ALGAMOIL AT THE WORLD CONGRESS OF ALGAL PRODUCTS MANUFACTURERS - SAN DIEGO - CALIFORNIA

The World Congress of algal products manufacturers was held from 29 September to 2 October. Great participation of visitors from all over the world; they paid almost $ 500 for entry.

Teregroup in cooperation with Algamoil was the only italian company and attracted considerable visitors interest.

During the congress, technological and biological news for algae development were submitted.

The producers got together to define algal products technical standards, in particular for establishing biofuels requirements. Teregroup research on biofuels has made it possible to define technical characteristics on diesel-power engines in series production.

More than 400 projects and searches were submitted during the congress: this is a clear indication of strong development of the sector, especially after reports the Rockefeller family had abandoned the petroleum-derived fuels sector to work with green fuels like algal fuels.

Boeing was present at the congress with a model of the new 787 dreamliner that will be able to work also with algal fuels

INNOVATIVE SOLUTION FOR THE REDUCTION OF CO2 AND PARTICULATE EMISSIONS FROM INTERNAL COMBUSTION ENGINES

in cooperation with Unimore Enzo Ferrari departement, Hpe, Stm and Algamoil and co-financed by Fondazione Crmo

The conference started the project that aims to check all experimental data presented at the 68th Conference of the Italian Thermal Machines Engineering Association of 11 September 2013 by Professors Enrico Mattarelli and Carlo Rinaldini from University of Modena e by Professor Valeri Golovitchev from Chalmers University of Technology.

The project aims to test algal methane-fuelled and algal biodiesel-fuelled diesel engines: the ignition of the so-called dual-fuel engine occurs through a port fuel injection of biodiesel and preblended methane.

It is planned to test also methane produced by biogas plants: this will allow us to have 100% italian biofuel.

A strong delegation of Italian and international investors interested was present at the conference.

The conference was introduced by Professor Giuseppe Cantore, tenured professor at DIEF (Engineering Department Ingegneria Enzo Ferrari), celebrating 100 years of Maserati. Later on Professor Enrico Matterelli took the floor presenting the research made on dual-fuel and the expected results shown in the table below.

At the end Professor Carlo Rinaldini gave an overview of the state of the art in the testing of diesel engines fuelled with Algamoil algal biodiesel recently presented in Detroit.

At the end of the conference guests were invited to visit Algamoil and Teregroup laboratories and algae fuel production plants.

THE CASE FOR ALTERNATIVE FUELS

At present, storing electrons on board vehicles is less practical and consumes more space and weight than either gasoline or diesel or hydrogen or CNG. (General Motors)

There would have to be compelling reasons to justify switching from petroleum for transport. Why? For one, as liquids, gasoline and diesel are easy to distribute. They are also energy-dense. A gasoline or diesel tank can be filled in a few minutes and carry the vehicle hundreds of miles more conveniently than any other fuel type.

ALGAE BASED BIOFUEL IN DETROIT

EXPERIMENTAL INVESTIGATION ON BIODIESEL FROM MICROALGAE AS FUEL FOR DIESEL ENGINES

With the decreasing availability of conventional fossil fuels, their rising costs and their contribution to the accumulation of carbon dioxide in the environment, it has become necessary to research alternative fuels for engines.

Biodiesel is one of the best option to fulfill this demand but there is an increasing motivation to limit the production of fuel from eatable resources. In this scenario Biodiesel from Algae appears a promising solution for partially or totally substitution of fossil fuel in Diesel engines.

This study is dedicated to the engine application of blend of Biodiesel manufactured by transerification reaction from Microalgae and Diesel Oil (B20). Experiments were carried out on a 4-cylinder, 4-stoke naturally aspirated Diesel Engine whose performance and emission where measured on a wide range of operating points. Results obtained with B20 has been compared with ones obtained using commercial Diesel Oil. It was found that B20 leads to a very small decrease of performance limited to higher loads while slight differences have been found in engine pollutant emissions. Regarding the last issue, one of the most interesting results has been the reduction of soot emission measured supplying the engine with the B20 mixture.

WHY USE ALGAE TO PRODUCE OIL?

Put simply, lipids in algae oil can be made into biodiesel, while the carbohydrates can be converted to ethanol. Algae are the optimal source for second generation bioethanol due to the fact that they are high in carbohydrates/polysaccharides and thin cellulose walls.

Bioethanol can be used as a biofuel which can replace part of the fossil-derived petrol. currently bioethanol is produced by fermenting sugars, which in the case of corn are derived from hydrolyzing starch. Algae species starch contents over 50 percent have been reported. with new technologies, cellulose and hemicellulose can be hydrolyzed to sugars creating the possibility of converting an even larger part of algal dry matter to ethanol.

Algae have a number of advantages over other land based crops when considering the algae to biofuels equation.

- much greater productivity than their terrestrial cousins

- non-food resource

- use otherwise non-productive land

- can utilize saline water

- can utilize waste co2streams

- can be used in conjunction with waste water treatment

- an algal biorefinery could produce oils, protein, and carbohydrates

- potential for culture in areas not used for crop production

- desert land

- ocean